| The drag chain system is mainly composed of drag chain, drag chain cable, guide groove and floating connector. Compared with the drag chain system, the drag chain system has better protection for the cable, thus prolonging the cable life. At the same time, since the towline system can start power supply from the middle of the stroke, it can save 50% of the cable length and further reduce the procurement cost of the power supply system. When the mobile equipment needs a continuous supply of electricity, water, gas and other media at the same time, compared to the need to set up multiple reels for the equipment, a drag chain system can meet all the above requirements, greatly simplifying the structure of the equipment and improving the stability of the equipment . |

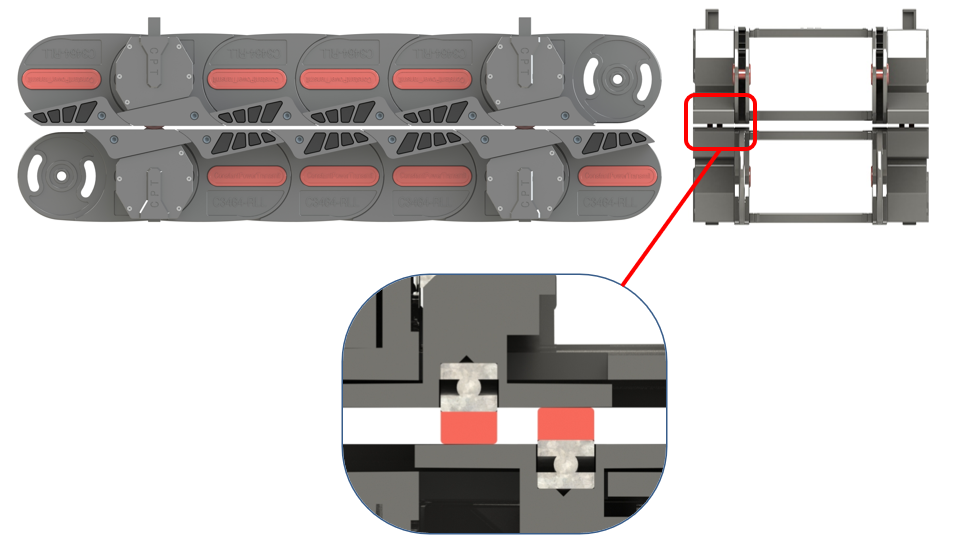

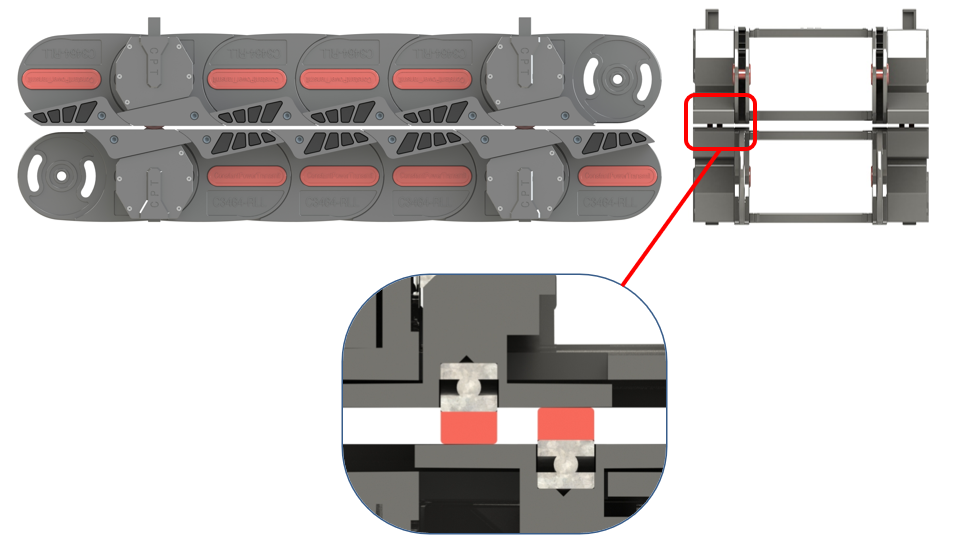

A great friction will occur between the upper layer and the lower layer of the conventional tow chain. The longer the stroke, the greater the friction, even up to the extent that the tow chain cannot be dragged and the devices cannot work normally. Adding fixed roller cannot only solve the great friction, but also brings collision and trampling between upper and lower tow chain rollers. In this case, we creatively developed a laterally movable roller module.

|  |

|

CPT drag chain system adopts a laterally movable roller structure, and the lower part compresses the trigger rod inwards under the action of gravity to push the roller to move. It can well solve the fluctuation and vibration of the tow chain caused by the overlapping of the conventional roller tow chain system, as shown above. This assures high-speed and silent operation. With this roller structure, the maximum speed of CPT long stroke tow chain can reach 10m/s, the resistance generated by the tow chain can be as low as 3N/m, and the longest stroke length can be 1,000m. In addition, due to the complete rolling friction, it can effectively avoid the "arching" during tow chain operation.

|